The Electrical Installation Department assures (takes part in):

- processing of the initial ideas of the investor, including the proposed project's basic features

- elaboration of the design documents and the production design documents using the ProfiCAD electrical software

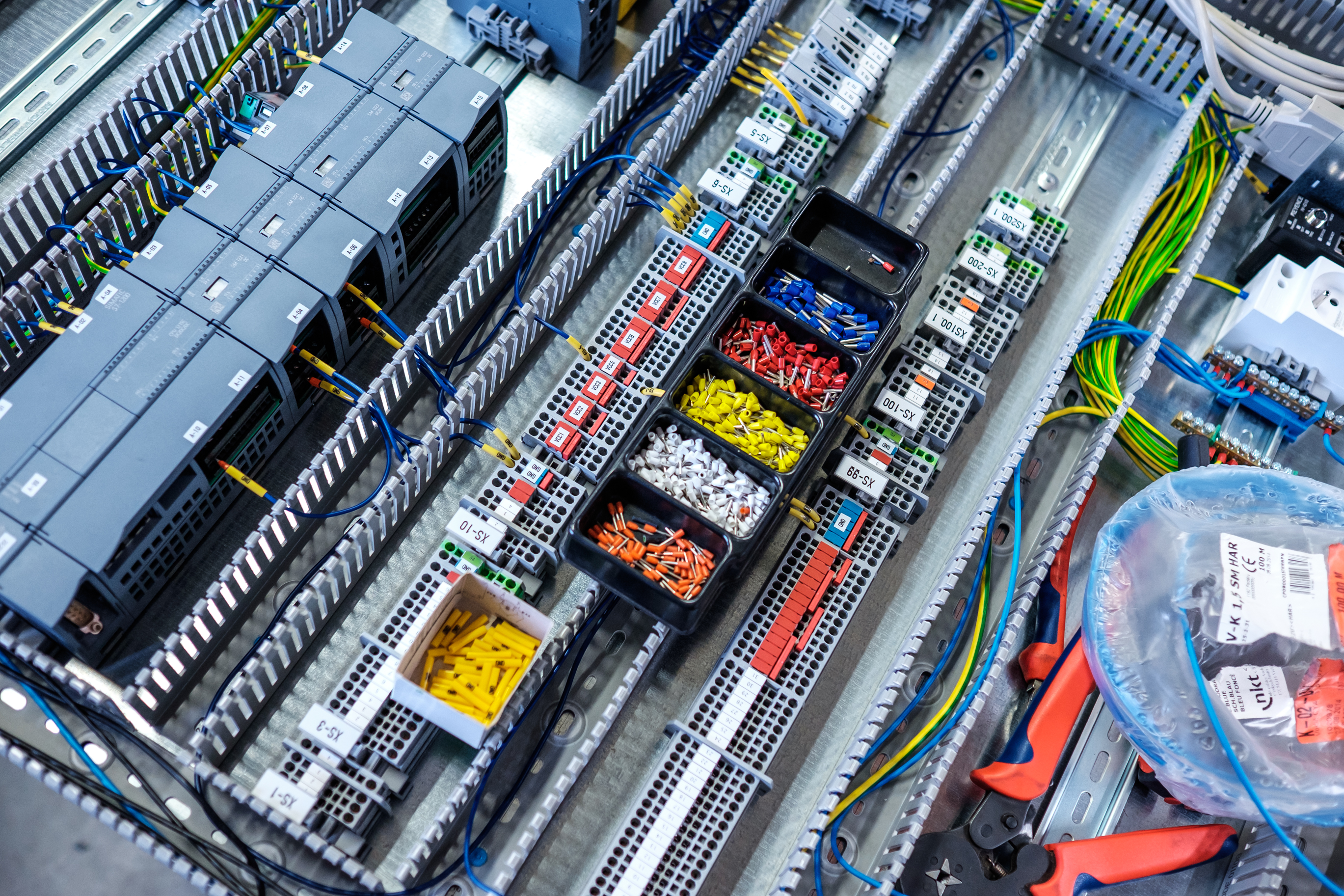

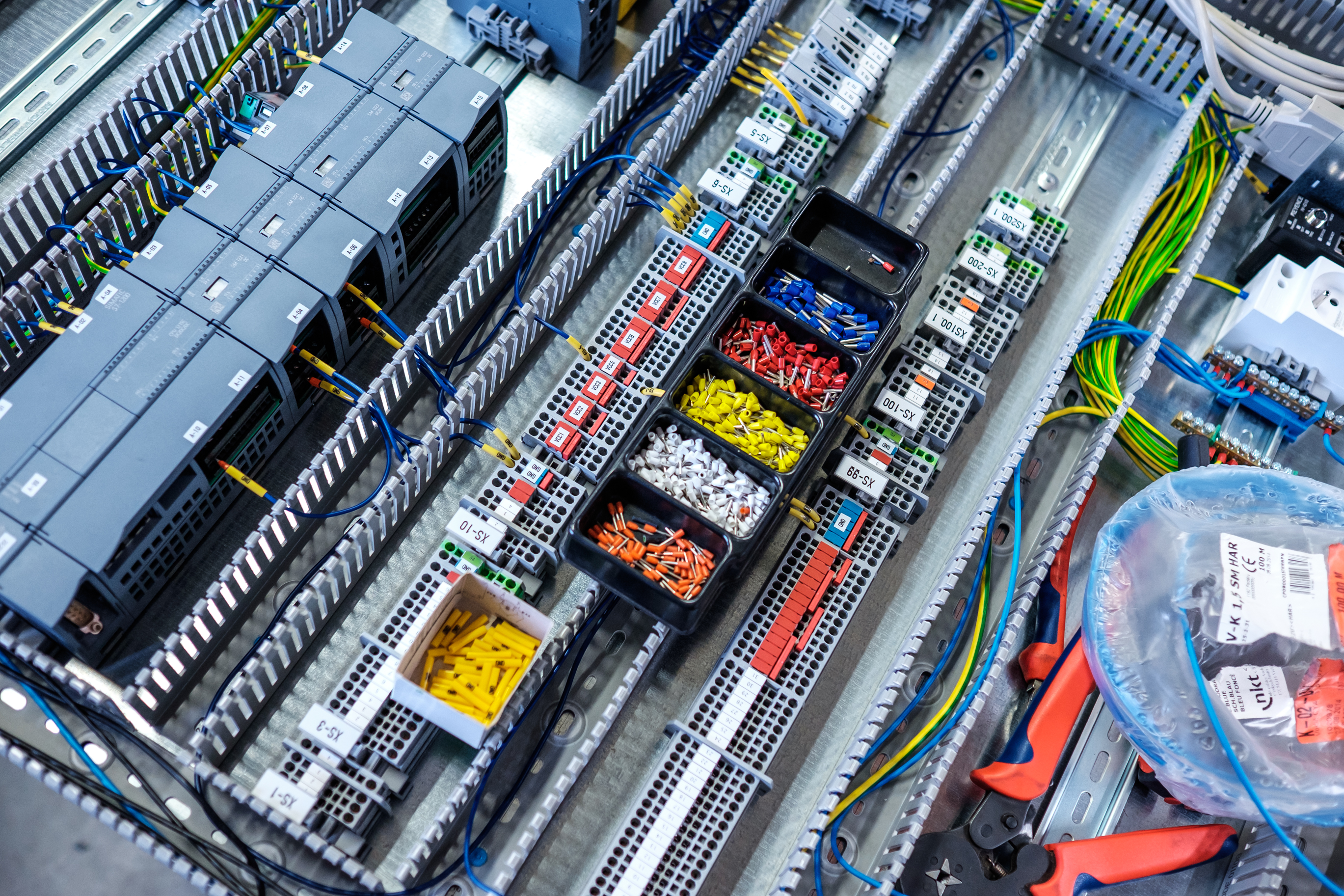

- software for the control systems of Siemens - S7 1200, 400, 300, LOGO , Schneider-Electric, Moeller, Phoenix Conact

- software for the operator panels (Siemens, Phoenix Contact, …) and visualization system (REXROTH)

- the control system conception with prospective utilization of the distributed control systems that communicate via the industrial buses

- selection of the sensing elements to detect the positions of machines and transported material (standard sensor system, RFID systems, IRC sensors, camera systems, …)

- utilization of the modern drive control elements – frequency converters, servo converters

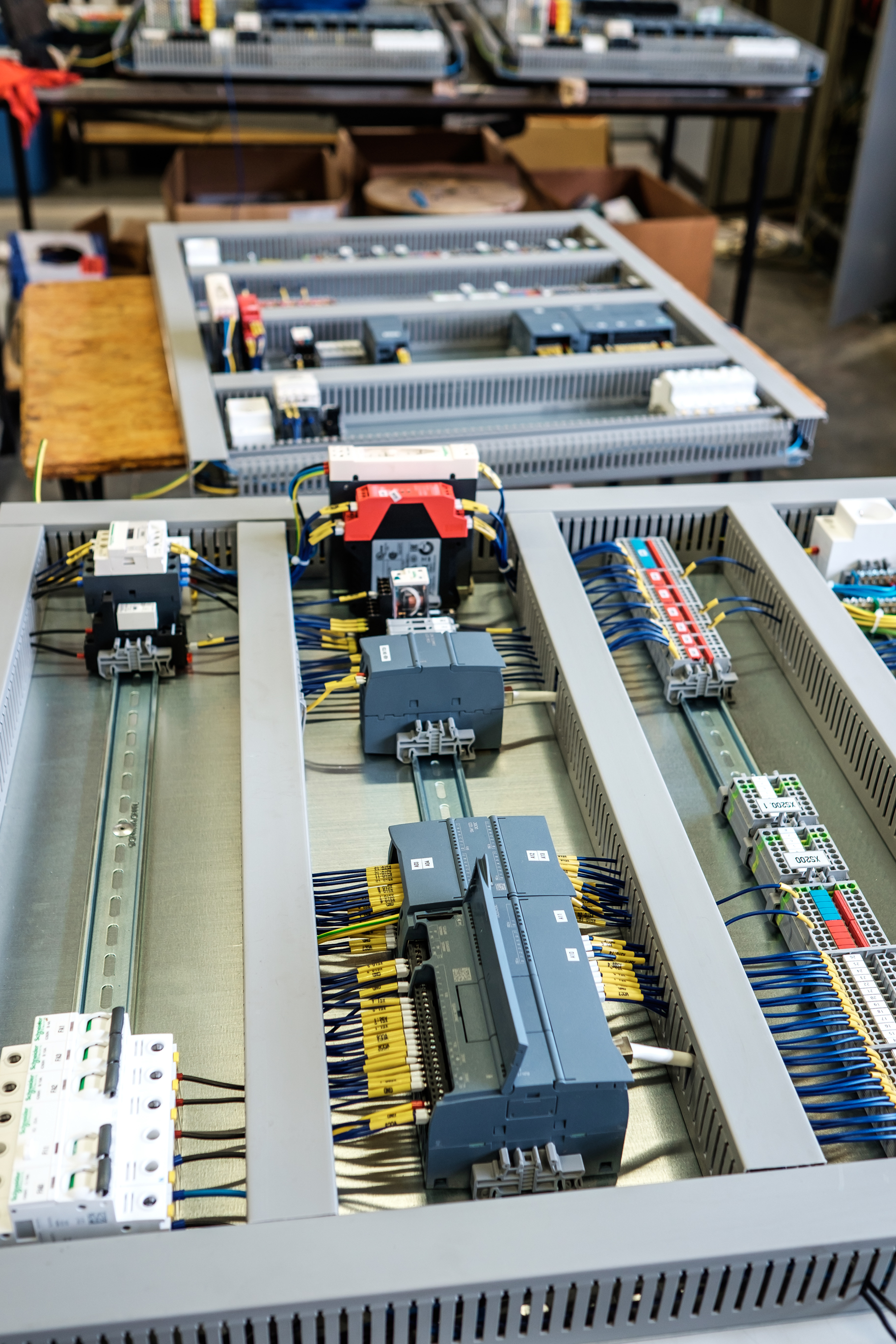

- production of switchboards and other electrical equipment, including its installation to the equipment

- wiring jobs in the customer site, in Ort Nový Bydžov, assembly and test of the machine function to quicken the implementation in the customer site

- putting into operation and training of operators, and revision

- initial revision

- warranty and post-warranty service

- relocation of the production lines and machines, including the adaptation to the new conditions

- reconstruction and reworking of machines

- robotization and full automation of workplaces

Selection of the components of electrical installation respects the customer requirements, components of the renown manufacturers are used.

Our services in the area of industrial automation and electrical installation include:

- development and production of transport systems and single-purpose machines

- deliveries in the field of industrial automation

- Production Process Automation

- assembly, repairs and revisions of the dedicated machinery and single-purpose equipment for electrical installation

- production of low-voltage switchboards, the entire LV wiring

Development and Production

We deliver complete turn-key equipment – project, production, installation, commissioning, and putting into operation. No less important part of our deliveries is the warranty and post-warranty service for the entire equipment life expectancy. We offer entering into Servicing Contracts to ensure regular care for the delivered equipment.

Switchboard Production

Application of the first quality components for electrical installation is a matter of course. Execution meets strict requirements imposed on the equipment, even in the environments with increased dust load and in the environments with vibrations and shocks. Careful and consistent designation of elements and wires makes orientation in the wiring easier. Switchboards are checked for function before dispatch.

Installation at Customer Site

Installation is performed by experienced workers with first quality tooling that conforms to the equipment to be installed. Elaborate execution of all the installed components. Precise execution of the cable routes minimizes the risk of cables damaged as a consequence of operation or unprofessional intervention of operator. As a matter of course, we designate all the implemented connections with labels and descriptors. This method of work proved to be effective owing to a substantial consequent improvement in transparency of the installation.

We are capable of solving various tasks of our customers in the industrial automation and robotization. We provide "turn-key" deliveries starting from the technical consultation through the project up to the implementation, putting into operation, and consequent support of the customer during operation of the aggregates delivered by our company.

Deliveries of all the spare electrical parts and mechanical components.